Significant acceleration of suppliers’ product data onboarding and go-to-market

We’ve managed to increase product velocity, and increase our product range for the vast majority of our suppliers.

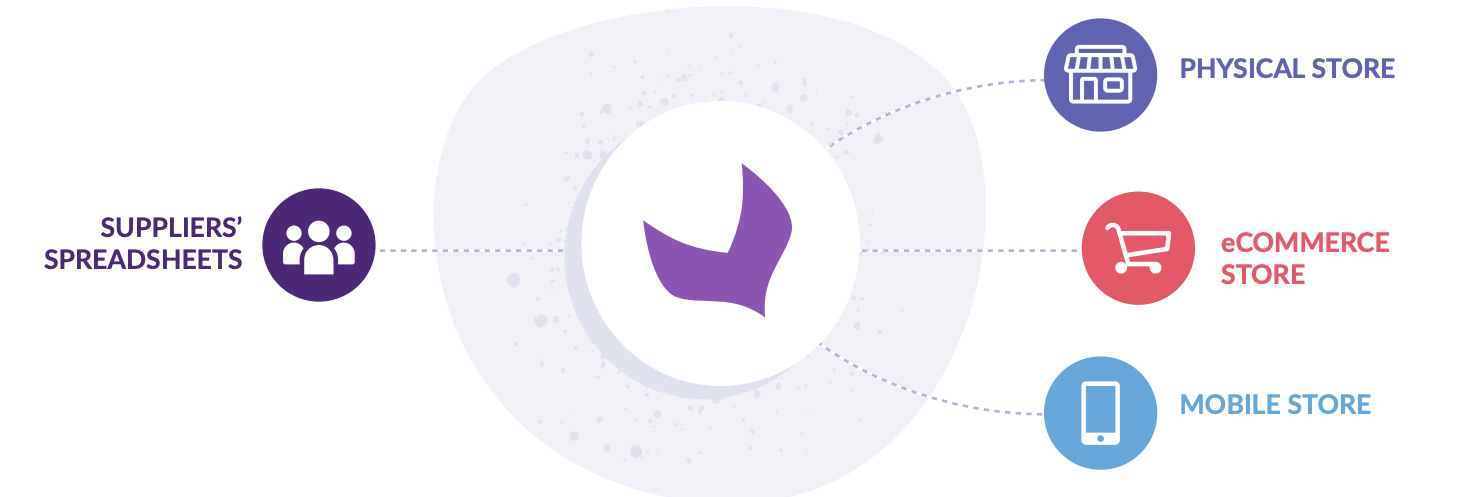

Myer is Australia’s oldest and largest department store, operating more than 60 stores, an eCommerce store, and mobile site. The company sells a range of products, including men’s, women’s, and children’s apparel, toys, home goods, entertainment products, and more.

While this massive selection has helped the company build its reputation as a one-stop-shop for Australians, it also presented a big challenge for the retailer. When product information was delivered by suppliers, it was often incorrect, inconsistent, or of low-quality. Some suppliers were not adhering to the company’s style guide, so when product information and assets arrived they were often non-compliant to guidelines — that is, if they arrived at all.

What’s more, product information and data was trapped and siloed in various spreadsheets and legacy file-sharing solutions. Suppliers, meanwhile, had no visibility into the enrichment process, whether they had delivered all of the necessary information, and didn’t know when (or if) the enrichment process would be completed.

As Myer continued its digital transformation, it was on the lookout for a PIM that could make it easier and more efficient for suppliers to provide consistent, accurate, and high-quality product information and slash time-to-market.

Products were getting online so slow that the products were on clearance by the time they were available online for sale, and may have even been out of stock.

Myer eventually elected to go with Akeneo PIM, thanks in large part to the company’s open-source platform and API offerings. Myer was eager to find a solution that offered customization, but didn’t force them to start from scratch — enter Akeneo PIM and its open source design.

After implementing Akeneo PIM, Myer quickly went to work teaching suppliers on how to use the solution to enrich their own product information. The company instituted a new grading and scoring system for product information and assets, which gave suppliers more transparency into the process, and helped them understand not only what information and assets they had already been provided but also which were still needed, thereby improving time-tomarket. The company also customized the solution to meet its specific and unique needs — namely a vast diversity in the number and variants of products it sells.

Myer is now using Akeneo to help suppliers upload data directly to the PIM, resulting in more compelling, consistent and accurate product information, an even more extensive and diverse product catalog, while significantly reducing time-to-market, among other benefits.

As a result of our Akeneo PIM implementation, our suppliers have told us that they are far happier with the enrichment process.

Faster time-to-market

Myer has significantly reduced their time-to-market, cutting the average enrichment time from more than 28 days down to less than seven. What’s more, the average product information enrichment process for one product has dropped from approximately 20 minutes before implementing PIM to nearly no time at all, thanks to Akeneo’s automated features. Suppliers are also now adding and enriching new products into the system — on average, around 30 percent of product information was enriched before Akeneo PIM was implemented, however, that figure has since grown to reach an average of 60 percent of product information.

Higher information quality

As enrichment speeds have improved, so has the quality of product information. Before implementing Akeneo PIM, Myer offered suppliers a style guide, but this was largely being ignored by suppliers and offered no visibility into what information still needed to be provided in order to complete the product enrichment process. Today, suppliers can easily see what information needs to be added or improved before a product can go live on Myer’s website, raising the quality of product information and assets and providing customers with a better shopping experience.

Stronger supplier relationships

Thanks to this increased speed and improved visibility into the enrichment process, Myer’s relationships with its suppliers have never been stronger. The company’s suppliers have said “that they are far happier with the enrichment process.” Myer has even found that suppliers actually enjoy the process of directly enriching their products, and appreciate being able to do so themselves, rather than waiting for the company to do it for them.

A special thanks to our partners who supported this project:

Our Akeneo Experts are here to answer all the questions you might have about our products and help you to move forward on your PXM journey.