PDM (Product Data Management) is a system that helps businesses centralize and manage product design data. Its primary goal is to not only improve collaboration but also streamline engineering workflows and maintain control over versioning and revisions. By organizing product data in a single source of truth, PDM boosts development and reduces errors while supporting more accurate product innovation.

Product Data Management (PDM) is a type of software that centralizes and controls product-related data, such as computer-aided design (CAD) files, drawings, and documentation. By managing versions, revisions, and access in a single system, PDM helps engineering and product teams collaborate more effectively and accelerate development. It ensures that everyone works from the latest data, improving efficiency and supporting faster, more reliable product innovation.

PDM Key Features:

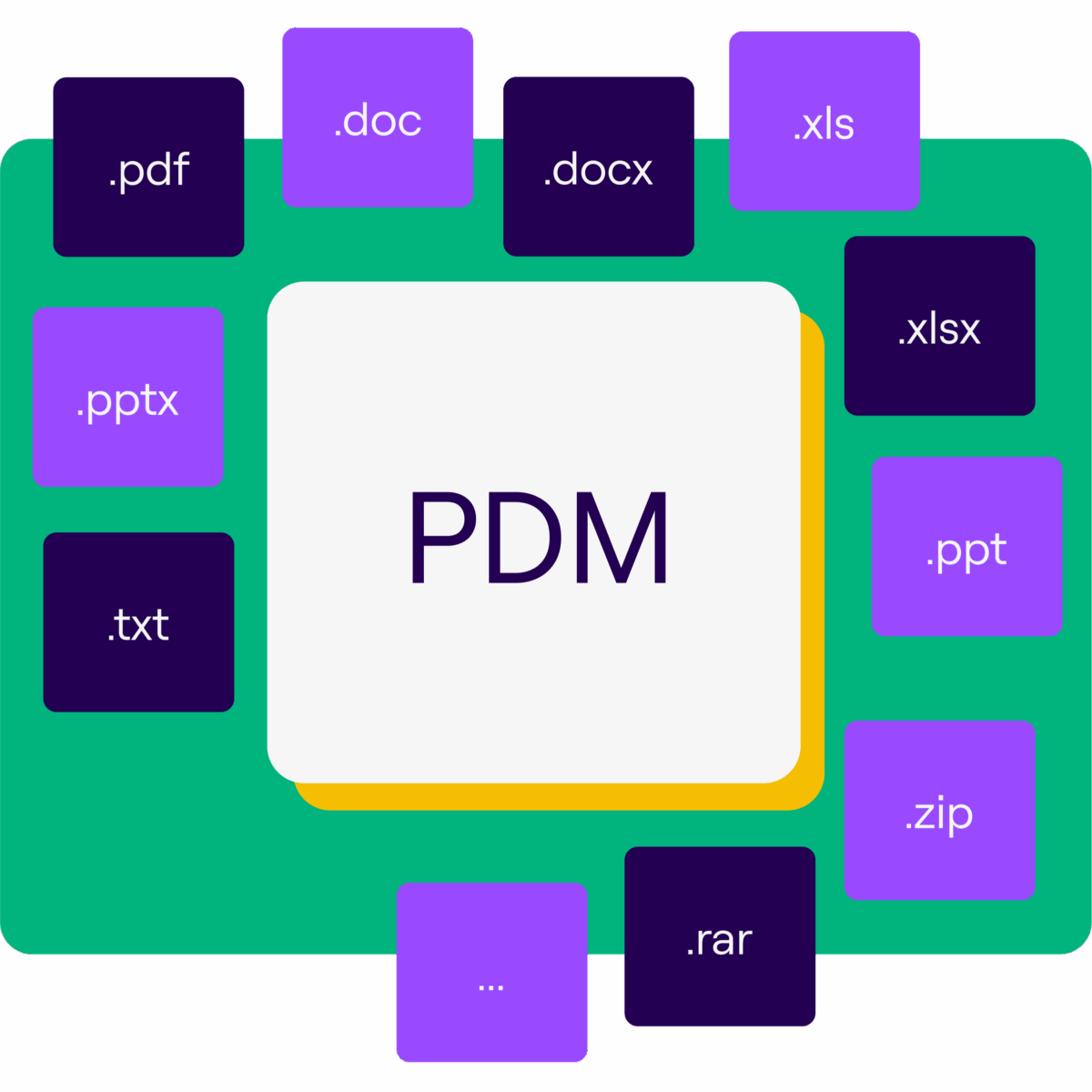

PDM systems store essential product design and development data, including CAD files, technical drawings, 3D models, engineering documentation, bills of materials (BOMs). They also manage version histories, change orders, part numbers, and metadata related to materials, specifications, and compliance. This centralized product data ensures teams work with accurate, up-to-date information throughout the design and development process.

PDM systems help streamline product development by organizing and controlling design data in a single, secure location. They reduce errors through version control, improve collaboration across teams, and accelerate time-to-market. With centralized access and structured workflows, PDM ensures data accuracy and supports better product quality throughout the lifecycle.

| Challenge | Impact |

|---|---|

| Can’t find the right file | Delays in product development and time-to-market |

| Using outdated design versions | Costly manufacturing errors or rework |

| Uncontrolled access to files | Security risks and unauthorized changes |

| No version control or audit trail | Confusion over which design is final or approved |

| Manual handoffs between teams | Slower workflows and missed deadlines |

| Siloed design data | Poor collaboration and misalignment across departments |

| Lack of change tracking | Missed updates leading to quality issues or compliance risks |

| Disconnected tools (CAD, PLM, ERP) | Inefficient processes and data inconsistency |

| Duplicate file storage across systems | Increased storage costs and error-prone data management |

| No centralized data governance | Difficulty maintaining product quality standards at scale |

While PDM focuses on managing technical product design data, Akeneo’s Product Information Management (PIM) and Shared Data Manager (SDM) solutions extend the value of that data downstream, enabling businesses to deliver accurate and engaging product experiences across channels.

Once product data is finalized in the PDM system, Akeneo PIM takes over to transform that data into compelling, channel-ready content. With support for rich attributes, multilingual content, and localized details, PIM ensures that teams receive the most accurate and complete product information to publish across websites, marketplaces, and other platforms.

Akeneo SDM centralizes and simplifies the collection and correction of product data from suppliers, bridging the gap between upstream and downstream operations. With collaborative Supplier Access, brands can share templates and data guidelines directly through the SDM portal, streamline file import and mapping, and adapt the process to either delegate, internalize, or collaborate on product data correction.

By connecting PDM with Akeneo’s PIM and SDM, businesses can reduce manual re-entry of product data and accelerate product launches across markets. Structured workflows, validation rules, and role-based permissions ensure that everyone is working from the same up-to-date source of truth.

PDM focuses on managing technical product data used in engineering and design, like CAD files, drawings, and specifications. PIM, on the other hand, is used to enrich, manage, and distribute product information for marketing, eCommerce, and customer-facing channels.

No, Akeneo PIM is not a replacement for a PDM. Instead, it complements your PDM system by ingesting finalized design data and turning it into enriched, market-ready content for all sales and marketing channels.

Akeneo SDM serves as a collaborative platform for collecting and normalizing product data, especially from suppliers or external partners. It ensures that only clean, validated data enters your PIM, improving overall product data quality and reducing time-to-market.

Yes, Akeneo PIM can integrate with most PDM or PLM solutions. These integrations allow you to automatically import essential technical data and avoid repetitive data entry, keeping your product content pipeline efficient and aligned from design to digital shelf.

By connecting PDM with Akeneo PIM and SDM, you’ll reduce manual tasks, improve data accuracy, streamline collaboration between teams, and accelerate time-to-market. You’ll also gain better control over how product content is localized and distributed across channels.

Not at all. While SDM is ideal for onboarding supplier data, it can also be used to collaborate with internal teams, subsidiaries, or partners who contribute product information. It supports a wide range of use cases where structured product data needs to be collected and shared.

No, but using them together offers the best results! PIM handles enrichment and omnichannel distribution, while SDM ensures upstream data from suppliers and other partners is accurate before it reaches the PIM. When combined with your PDM system, this creates a seamless product information ecosystem from concept to customer.

Our Akeneo Experts are here to answer all the questions you might have about our products and help you to move forward on your PX journey.